Revolutionary CO2 Conversion Technology

In the quest to combat climate change, researchers at Aarhus University (AU) have unveiled a groundbreaking technology that uses microorganisms to convert CO2 from industrial flue gases into valuable resources such as fuels and chemicals. Unlike traditional carbon capture and storage (CCS), which traps CO2 and stores it underground, this innovative method transforms CO2 into raw materials for new applications. The findings, published in Nature Communications, mark a significant step toward a sustainable future.

“In a net-zero future, we need to use technology that recycles the CO2 we capture instead of continuing to extract more from the ground,” explains Amalie Kirstine Hessellund Nielsen, a PhD student at the Department of Biological and Chemical Engineering and one of the lead authors of the study.

Biological Integration in CO2 Reduction

Globally, flue gases from industrial chimneys are among the largest contributors to greenhouse gas emissions. These gases are particularly challenging to treat because CO2 is mixed with other compounds, making separation costly and energy-intensive. Traditional carbon capture methods rely on amine scrubbing, where chemicals bind to CO2, which is then released at high temperatures in a closed circuit. The concentrated CO2 is either stored or used in other industrial processes.

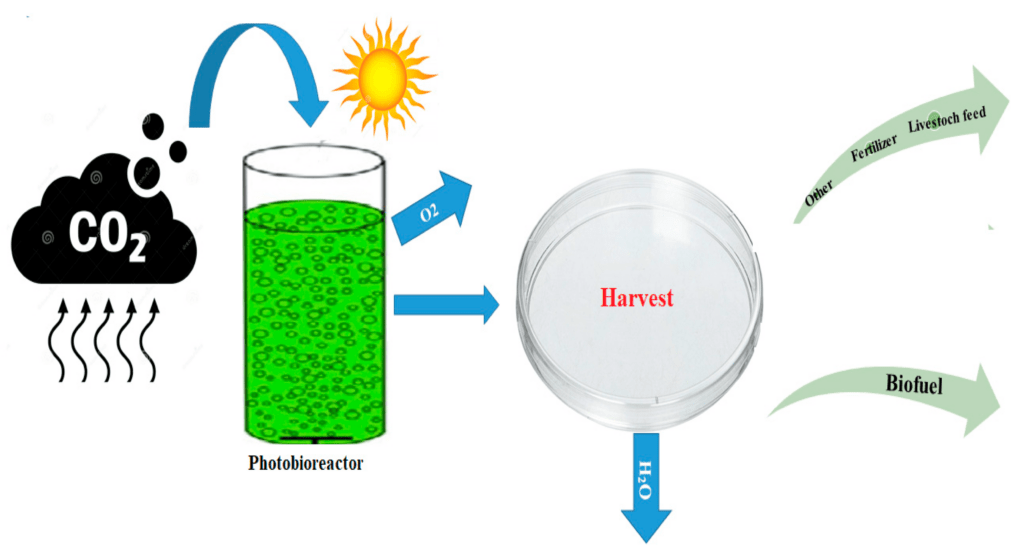

The new technology, dubbed bio-integrated carbon capture and utilization (BICCU), bypasses many of these intermediate steps. Instead of using heat to separate CO2, the researchers employ microorganisms that directly capture and convert CO2 within the system. This biological process operates at much lower temperatures, significantly reducing energy costs.

“Microorganisms are hyper-specialized in absorbing and converting CO2, a process they’ve refined over billions of years. We exploit this in our bioreactors,” says Mads Ujarak Sieborg, a postdoc at the Department of Biological and Chemical Engineering and the study’s lead author.

How It Works

The BICCU (Bio-Integrated Carbon Capture and Utilization) system represents a groundbreaking innovation in carbon capture and utilization technology. It integrates two key components—amine scrubbing and microbial conversion—to not only capture carbon dioxide (CO2) from industrial emissions but also transform it into valuable industrial materials, fostering a circular carbon economy. Here’s a deeper look at how this system works and its significance:

1. Amine Scrubbing: Capturing CO2 Efficiently

The first stage of the BICCU system involves amine scrubbing, a well-established method for carbon capture. In this process, flue gas—produced by industrial activities such as power generation or manufacturing—is directed through a column filled with amine-based chemicals. These chemicals have a high affinity for CO2, allowing them to selectively capture and bind the carbon dioxide molecules from the gas stream. The CO2 is then dissolved into a liquid solution, effectively removing it from the emissions.

This step is critical because it isolates CO2 from other gases, such as nitrogen and oxygen, which are typically present in flue gas. By concentrating the CO2 in liquid form, the system prepares it for the next stage of transformation, ensuring that the carbon is not merely stored but actively utilized.

2. Microbial Conversion: Turning CO2 into Valuable Products

The second stage of the BICCU system is where the real innovation lies. The CO2-laden liquid from the amine scrubbing process is transferred to a bioreactor column, where microorganisms and hydrogen are introduced. These microorganisms, often specially engineered strains of bacteria or archaea, are capable of metabolizing CO2 in the presence of hydrogen. Through a series of biochemical reactions, the microbes convert the captured carbon into useful products such as methane (CH4), acetic acid, or even more complex organic compounds.

- Methane: This can be used as a renewable natural gas, providing a sustainable energy source for heating, electricity generation, or industrial processes.

- Acetic Acid: A versatile chemical used in the production of plastics, textiles, and food preservatives.

- Other Products: Depending on the microbial strains and conditions, the system can also produce biofuels, bioplastics, or other high-value chemicals.

This microbial conversion process is highly efficient and sustainable, as it leverages natural biological pathways to recycle carbon rather than relying on energy-intensive chemical synthesis.

Creating a Circular Carbon Economy

The BICCU system goes beyond traditional carbon capture and storage (CCS) methods by not only capturing CO2 but also converting it into economically valuable products. This approach aligns with the principles of a circular carbon economy, where carbon emissions are treated as a resource rather than a waste product. By transforming CO2 into industrial materials, the system reduces the need for fossil fuel-derived inputs, thereby lowering overall carbon emissions and promoting sustainability.

The BICCU system exemplifies the future of carbon management, combining cutting-edge chemical and biological processes to address one of the most pressing challenges of our time: climate change. By integrating amine scrubbing and microbial conversion, it not only captures CO2 but also transforms it into useful products, paving the way for a sustainable, circular carbon economy. This innovative approach demonstrates how technology can turn environmental challenges into opportunities, offering a blueprint for industries worldwide to reduce emissions while driving economic growth.

Practical Applications and Future Potential

While carbon capture technologies are still in their infancy, the potential applications of BICCU are vast. Biogas plants, which produce waste gases with high CO2 concentrations (up to 50%), have already begun adopting carbon capture. However, traditional industries, such as power plants, face greater challenges due to lower CO2 concentrations (5-10%) in their flue gases.

The high energy costs of conventional carbon capture—accounting for about 30% of a power plant’s total energy output—have limited its adoption. The microbiological approach offers a more cost-effective alternative, as it eliminates the need for energy-intensive heating processes.

“The biological process operates at much lower temperatures, and our microbes are resistant to other gases in the flue gases,” says Nielsen. “However, hydrogen is a limiting factor in the system, so there are still challenges to address.”

Challenges and Solutions

One of the primary hurdles is the reliance on hydrogen, which is currently produced through electrolysis. Scaling up hydrogen production sustainably will be crucial for the widespread adoption of BICCU technology. Additionally, integrating the system into existing industrial infrastructure requires careful planning and optimization.

Despite these challenges, the researchers are optimistic. “We already have a wide range of reactors to test—it’s primarily a question of putting the system together correctly,” says Nielsen.

A Step Toward Net Zero

The BICCU technology represents a small but critical component of the global effort to achieve net-zero emissions. While it cannot replace renewable energy sources, it offers a complementary solution for reducing industrial carbon footprints.

“CCU is a necessary element in the green transition, ensuring that greenhouse gas emissions and removals are balanced,” says Nielsen. “However, renewable energy remains the most important tool in combating climate change.”

A Greener Future

The development of CO2-eating bacteria and bio-integrated carbon capture systems marks a significant milestone in the fight against climate change. By transforming industrial emissions into valuable resources, this technology not only reduces reliance on fossil fuels but also paves the way for a circular carbon economy.

As we stand on the brink of a sustainable future, the question remains: Are we ready to embrace innovative solutions like BICCU and take bold steps toward a greener planet?

Related Content

- Less Waste, More Building: How Bacteria Can Heal Concrete

- Rozino Bee Venom: A Natural Wonder for Skin and Beyond

- Bamboo: The Eco-Friendly Wonder Material Transforming Modern Design

- Tesla’s Shift to Hydrogen Fuel Cells: A New Era of Innovation and Sustainability

- Giant Catapult Defies Gravity by Launching Satellites Without Rocket Fuel

- E-Fuels Pioneer Announces Major Project in Brazil: A Step Toward Cleaner Energy

- Toyota’s Green Fuel Engine: A Versatile Approach to Sustainability

- Green Hydrogen: A Brighter Future Fueled by Sunlight and Water?

- Top Countries by Fossil Fuel Consumption in 2023: Growth, Sustainability, and Ecological Impact

- Chonkus: A Carbon-Hungry Microbe Revolutionizing Carbon Capture

- Coral as a Microplastic Sink: A New Solution to the Ocean Plastic Crisis

- Brittany’s Dark Secret: The Polluted Paradise of Saint-Michel-en-Grève

- CO2-Eating Bacteria Turn Chimney Smoke

- Turning Chimney Smoke into Sustainable Fuel with CO2

- Gregory Spiller “The Digital Diogenes”‘s Post

- CO2-eating bacteria recycles carbon from chimney smoke